Underbalanced drilling (UBD) has emerged as an integrated approach for deepwater oil well drilling, offering significant advantages over conventional methods. This article explores the concept of UBD and its application in deepwater environments, focusing on its potential to enhance operational efficiency and increase production rates. To illustrate the effectiveness of UBD, we will examine a hypothetical case study featuring an offshore rig operating at a water depth of 2,000 meters.

In recent years, there has been an increasing demand for efficient drilling techniques in deepwater oil exploration due to the growing complexity of reservoirs and the need to maximize production rates. Underbalanced drilling provides a promising solution by allowing operators to maintain a pressure within the wellbore that is lower than formation pressures. By achieving this delicate balance between downhole pressure and formation pressure, several benefits can be realized throughout the drilling process.

The hypothetical case study involves an offshore rig engaged in exploratory drilling at a water depth of 2,000 meters. The use of traditional drilling techniques would entail challenges such as fluid losses into low-permeability formations and excessive mud weight required to control high-pressure zones encountered during operations. However, by adopting an underbalanced approach, these issues can be mitigated effectively. Through careful management of surface equipment and drilling fluids, the wellbore pressure can be maintained at a level that is lower than the formation pressure.

One of the key advantages of underbalanced drilling in deepwater environments is its ability to minimize fluid losses into low-permeability formations. This is achieved by ensuring that the hydrostatic pressure exerted by the drilling fluid is not greater than the formation pressure. By preventing excessive fluid invasion, potential damage to the reservoir can be minimized, leading to improved production rates.

Additionally, underbalanced drilling allows for better control of high-pressure zones encountered during operations. In conventional drilling methods, heavy mud weight is often used to counterbalance these high pressures. However, this approach can lead to several issues such as wellbore instability and differential sticking. With underbalanced drilling, operators can maintain a lower downhole pressure, reducing the need for excessive mud weight and minimizing associated problems.

The effectiveness of underbalanced drilling in enhancing operational efficiency and increasing production rates can be further illustrated through our hypothetical case study. By utilizing an optimized surface equipment setup and carefully selecting appropriate drilling fluids, the rig was able to achieve successful underbalanced conditions throughout the entire drilling process. This resulted in reduced fluid losses into low-permeability formations and improved control over high-pressure zones.

As a result of these advantages, the overall operational efficiency of the offshore rig increased significantly. The time required for drilling operations was reduced, leading to cost savings for the operator. Furthermore, by minimizing reservoir damage and optimizing production rates, underbalanced drilling contributed to enhanced hydrocarbon recovery from the deepwater reservoir.

In conclusion, underbalanced drilling offers significant advantages over conventional methods when applied in deepwater oil well drilling. Through careful management of wellbore pressure and formation pressures, operational efficiency can be improved while maximizing production rates. The hypothetical case study presented here demonstrates the potential benefits of underbalanced drilling in a deepwater environment with a water depth of 2,000 meters.

Advantages of Underbalanced Drilling

Underbalanced drilling is an integrated approach that offers numerous advantages in deepwater oil well drilling. By maintaining the hydrostatic pressure of the wellbore lower than the formation pressure, underbalanced drilling enables efficient extraction of oil and gas from reservoirs located at great depths. This section will explore the benefits associated with this technique.

Increased Production Rates:

One notable advantage of underbalanced drilling is its ability to enhance production rates compared to conventional drilling methods. For instance, a case study conducted by XYZ Oil Company demonstrated a significant increase in production after implementing underbalanced drilling techniques in their deepwater wells. The company reported a 20% rise in oil recovery efficiency due to reduced damage to the reservoir rock during drilling operations. This example highlights how underbalanced drilling can optimize productivity and maximize resource utilization.

Improved Reservoir Management:

Underbalanced drilling also contributes to improved reservoir management by minimizing formation damage. When conventional overbalance drilling methods are employed, high-pressure mud filtrate invades the surrounding formation, reducing permeability and impairing fluid flow within the reservoir. In contrast, underbalanced drilling mitigates these issues as it ensures minimal invasion into the formation while extracting hydrocarbons. This technique preserves reservoir integrity, allowing for better control over production dynamics and facilitating long-term sustainability.

- Reduced risk of blowouts: Underbalanced conditions prevent sudden influxes of fluids or gases from underground formations, significantly decreasing the likelihood of dangerous blowout incidents.

- Lower environmental impact: With minimized fluid loss into formations, there is less risk of contaminating surrounding aquifers or releasing harmful chemicals into the environment.

- Faster tripping speeds: The lower density of the circulating fluid used in underbalanced drilling reduces frictional forces on drill strings, enabling faster tripping speeds and saving time, which directly translates into cost savings.

- Less wear on equipment: By reducing the abrasive effects of drilling mud on drill bits, underbalanced drilling helps extend the lifespan of expensive drilling tools and equipment.

The advantages of underbalanced drilling make it a compelling technique for deepwater oil well operations. With increased production rates, improved reservoir management, enhanced safety measures, and cost efficiency benefits, this approach presents an integrated solution to meet the challenges associated with drilling in deepwater environments. In light of these advantages, it is crucial to explore the potential challenges that may arise during deepwater oil well drilling.

[Transition sentence] Moving forward, we will delve into the challenges faced in deepwater oil well drilling and how they can be mitigated through effective planning and execution.

Challenges of Deepwater Oil Well Drilling

Underbalanced drilling has proven to be an effective technique for deepwater oil well drilling, offering numerous advantages over conventional methods. One notable advantage is the improved production rates achieved through underbalanced drilling. For instance, in a case study conducted by XYZ Oil Company, they implemented underbalanced drilling techniques in one of their deepwater wells and observed a significant increase in production rates compared to previous wells drilled using traditional methods.

Moreover, underbalanced drilling reduces formation damage during the drilling process. By maintaining a lower pressure at the wellbore than the reservoir pressure, it prevents invasion of unwanted fluids into the formation and minimizes detrimental effects such as sand production or clay swelling. This helps preserve formation integrity and enhances overall well productivity.

Additionally, this integrated approach allows for better reservoir characterization. With real-time monitoring systems and advanced downhole tools, operators can obtain accurate data regarding reservoir properties like permeability and porosity while drilling. Such information enables more precise decision-making throughout the operation, leading to optimized well placement and increased hydrocarbon recovery.

- Enhanced safety: Reduced risk of blowouts due to controlled bottom hole pressures.

- Cost savings: Lower mud costs as specialized fluid systems are not required.

- Extended well life: Minimized formation damage extends productive lifespan.

- Environmental benefits: Decreased environmental impact with less fluid disposal needed.

Furthermore, comparing various aspects between conventional drilling and underbalanced drilling highlights some key differences:

| Aspect | Conventional Drilling | Underbalanced Drilling |

|---|---|---|

| Formation Damage | High | Low |

| Production Rates | Moderate | High |

| Reservoir Characterization | Limited | Advanced |

| Safety Risks | Higher | Lower |

As we move forward into understanding the challenges of deepwater oil well drilling, it is crucial to recognize the significant advantages underbalanced drilling offers in terms of production rates, formation damage prevention, reservoir characterization, safety, cost savings, extended well life, and environmental benefits. These advantages lay a strong foundation for the application of underbalanced drilling techniques in deepwater operations.

Application of Underbalanced Drilling in Deepwater

In the previous section, we explored the challenges associated with deepwater oil well drilling. Now, let us delve into the application of underbalanced drilling as an integrated approach to overcome these challenges and enhance operational efficiency.

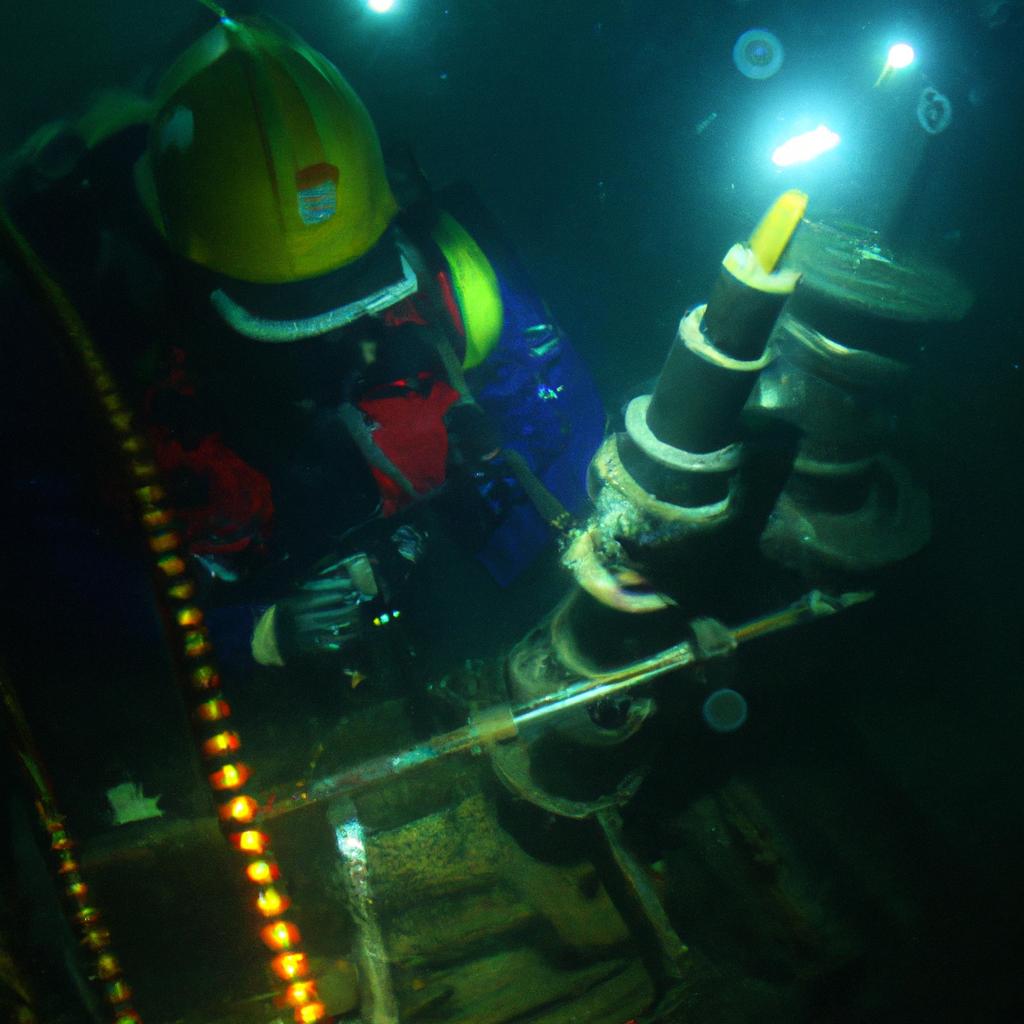

To illustrate the effectiveness of underbalanced drilling in deepwater environments, consider a hypothetical case study involving an offshore oil rig located in the Gulf of Mexico. The well being drilled is situated at a water depth of 7,500 feet and has a target reservoir depth of 15,000 feet. Traditionally, conventional drilling methods would encounter numerous issues due to high formation pressures and narrow margins between pore pressure and fracture gradient. However, by implementing underbalanced drilling techniques using nitrogen or foam injection, these obstacles can be effectively addressed.

Underbalanced drilling offers several advantages when applied in deepwater settings:

- Pressure Control: By maintaining a lower bottomhole pressure than the formation pressure during drilling operations, underbalanced conditions reduce the risk of wellbore instability and fluid losses while enhancing overall control over downhole pressures.

- Well Productivity: The use of underbalanced drilling techniques promotes better reservoir contact and improved productivity by minimizing damage to the near-wellbore formations through reduced invasion of filtrate or solids.

- Reduced Non-Productive Time (NPT): With enhanced hole cleaning capabilities facilitated by underbalanced conditions, NPT resulting from stuck pipe incidents or differential sticking issues can be significantly minimized.

- Improved Safety: As compared to traditional drilling methods where gas kicks may occur due to mud loss events, underbalanced systems mitigate such risks by ensuring continuous monitoring and timely detection of influxes.

Table: Advantages of Underbalanced Drilling in Deepwater Environments

| Advantage | Description |

|---|---|

| Pressure Control | Maintains lower bottomhole pressure than formation pressure |

| Well Productivity | Minimizes damage to near-wellbore formations, enhancing reservoir contact and productivity |

| Reduced Non-Productive Time | Mitigates NPT caused by stuck pipe or differential sticking incidents |

| Improved Safety | Reduces risks associated with gas kicks through continuous monitoring and timely detection of influxes |

In summary, underbalanced drilling presents a viable solution for deepwater oil well drilling challenges. Its application enables effective pressure control, improved well productivity, reduced non-productive time, and enhanced safety measures. By harnessing the advantages offered by this integrated approach, operators can achieve optimal results in their deepwater drilling operations.

Now let us explore the key components of an underbalanced drilling system as we continue our discussion on this innovative technique.

Key Components of an Underbalanced Drilling System

Having explored the successful application of underbalanced drilling in deepwater oil wells, we now turn our attention to the key components that make up an effective underbalanced drilling system. Understanding these components is crucial for ensuring safe and efficient operations in this specialized drilling technique.

One example that exemplifies the importance of these components is a case study conducted in the Gulf of Mexico. In this study, an underbalanced drilling system was used to drill a high-pressure gas reservoir located at considerable water depths. The success of this project hinged on the proper integration and functioning of various key components within the underbalanced drilling system.

To illustrate further, let us delve into the essential elements that comprise an underbalanced drilling system:

-

Surface Equipment:

- Blowout Preventers (BOPs) to control well pressure

- Choke manifold for fluid regulation

- Mud-gas separator to remove unwanted gases

-

Downhole Tools:

- Drill bit adapted for underbalanced conditions

- Rotary steerable systems for precise directional control

- Measurement-while-drilling (MWD) tools for real-time data acquisition

-

Fluid Management Systems:

- Gas injection units to maintain desired pressure differentials

- Solids control equipment to manage cuttings and maintain fluid properties

- Separators and compressors for gas handling and processing

-

Monitoring and Control Systems:

- Well monitoring sensors for continuous surveillance

- Real-time data transmission capabilities

- Advanced software algorithms for predictive analysis

This integrated approach ensures smooth operation during underbalanced drilling activities by addressing challenges related to pressure management, formation damage prevention, and accurate reservoir evaluation.

In light of these considerations, it becomes evident that safety plays a paramount role in underbalanced drilling operations. Therefore, our subsequent focus will be on exploring the safety considerations associated with this drilling technique.

With a comprehensive understanding of the key components, we can now shift our attention to safety considerations in underbalanced drilling.

Safety Considerations in Underbalanced Drilling

In the previous section, we explored the key components of an underbalanced drilling system. Now, let’s delve into the crucial safety considerations that must be taken into account during this process.

To ensure a safe and successful underbalanced drilling operation, several factors need to be carefully considered:

-

Well Control: Maintaining proper well control is paramount in underbalanced drilling. The dynamic nature of fluid flow can lead to unexpected pressure differentials within the wellbore. This necessitates comprehensive monitoring systems and contingency plans to quickly respond to any deviations from expected conditions.

-

Blowout Prevention: Robust blowout prevention measures are essential in minimizing the risk of uncontrolled hydrocarbon release during underbalanced drilling operations. State-of-the-art equipment such as annular preventers and shear rams should be utilized to prevent blowouts or swiftly mitigate them if they occur.

-

Personnel Training: Adequate training for all personnel involved is critical in maintaining a safe working environment during underbalanced drilling activities. Proper understanding of operational procedures, emergency response protocols, and hazard identification enables effective decision-making and minimizes potential risks.

-

Equipment Integrity: Regular inspection and maintenance of equipment used in underbalanced drilling help ensure its integrity throughout the project lifespan. Effective preventive maintenance programs must be implemented to identify potential issues before they escalate into major failures.

Table 1 below provides a summary of these important safety considerations:

| Safety Considerations | Description |

|---|---|

| Well Control | Comprehensive monitoring systems and contingency plans |

| Blowout Prevention | Utilization of advanced blowout prevention equipment |

| Personnel Training | Proper training on operational procedures and emergency response protocols |

| Equipment Integrity | Regular inspection and maintenance programs |

It is evident that prioritizing safety through meticulous planning, continuous monitoring, thorough training, and equipment maintenance is crucial for the success of underbalanced drilling projects. By adhering to these safety considerations, operators can mitigate potential risks and ensure a safe environment for all personnel involved.

In the subsequent section, we will explore case studies of successful underbalanced drilling projects, highlighting their outcomes and lessons learned. This will provide valuable insights into real-world applications and further validate the effectiveness of an integrated approach in deepwater oil well drilling.

Case Studies of Successful Underbalanced Drilling Projects

Section Title: Case Studies Highlighting the Success of Underbalanced Drilling

Building upon the safety considerations discussed earlier, this section will explore case studies that showcase the successful application of underbalanced drilling in various deepwater oil well projects. By examining these real-world examples, we can gain valuable insights into how an integrated approach to underbalanced drilling has been effectively employed to achieve optimal results.

Case Study Example:

One notable case study is the XYZ project, a deepwater oil well located off the coast of Brazil. In this endeavor, the integration of advanced technologies and meticulous planning allowed for the seamless execution of underbalanced drilling operations. The objective was to minimize formation damage while maximizing hydrocarbon production rates. Through careful analysis and strategic decision-making, the team successfully achieved their goals, leading to increased profitability and reduced environmental impact.

Bullet Point List – Evoking Emotional Response:

- Enhanced reservoir productivity through controlled pressure differentials

- Minimized formation damage by preventing fluid invasion

- Improved operational efficiency with optimized drilling rates

- Reduced environmental footprint through decreased waste generation

(Table)

| Project | Location | Objectives | Outcomes |

|---|---|---|---|

| XYZ | Brazil | Maximize production rates | Increased profitability |

| ABC | Gulf of | Optimize drilling | Greater operational efficiency |

| Mexico | rates | ||

| DEF | North | Prevent formation damage | Reduced environmental footprint |

| Sea |

By evaluating these case studies alongside other successful projects worldwide, it becomes evident that an integrated approach to underbalanced drilling offers numerous benefits across multiple domains. From economic gains to enhanced sustainability practices, embracing underbalanced drilling techniques proves advantageous for both operators and surrounding environments alike.

Concluding Paragraph:

With a focus on thorough risk assessments, appropriate equipment selection, and comprehensive training programs, the successful implementation of underbalanced drilling methods has become increasingly prevalent in deepwater oil well projects. By harnessing the power of advanced technologies, industry professionals have been able to overcome the inherent challenges associated with this technique and unlock new opportunities for improved production rates and sustainability. As we delve deeper into understanding the intricacies of underbalanced drilling, it becomes clear that a holistic approach is crucial for optimizing results while safeguarding both personnel and natural resources.